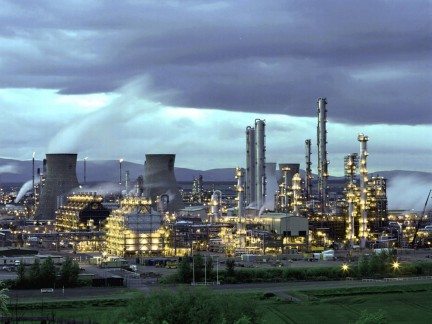

Chemicals industry: UK manufacturing’s unique element

Thursday, 2 Dec 2015

The roots of the UK’s chemicals industry extend deep into the past and it is still a vibrant element in the UK economy. Ruari McCallion takes a litmus test.

Any consideration of the UK’s chemical industry cannot ignore the role of ICI – Imperial Chemical Industries – which was, for almost 70 years, the country’s largest manufacturing business.

It was a huge company with interests sprawling across pharmaceuticals, agrichemicals; polymers; paints; commodity chemicals; industrial chemicals, and fibres. Its inventions included polythene; PET (polyethylene terephthalate – Terylene, as it was known); Perspex; Dulux paints (jointly with DuPont); Crimplene polyester yarn, and various pharmaceuticals.

Agrichemical products included herbicides and other pest control agents. It made soda ash products and its Nobel division made explosives. Britain’s industrial landscape owes a lot to ICI but this is not mere nostalgia; the legacy persists today.

It was stimulated to divest to a more manageable structure after rebuffing an attempted takeover by Hanson Corporation in the early 1990s. The pharmaceutical side was spun off and became AstraZeneca PLC. It bought Unilever’s speciality chemicals business of Unilever in 1997 and sold it to WR Grace the following year.

The Nylon business went to DuPont. It moved away from commodity chemicals and sold Tioxide, its titanium dioxide business, to Huntsman. Industrial chemicals went to Ineos; the remaining company, focused on paints, was acquired by Akzo Nobel in 2007.

The EC takes more than half (57%) of the UK industry’s exports; North America takes 18% and Asia and Oceania together account for 11%.

What is the industry making – and exporting?

Actually, it’s quite difficult to be precise. The largest subsector, according to the Standard Industrial Classification (SIC) system, is “other” – i.e., chemicals not classified elsewhere; it amounted to 11% of the industry’s GVA in 2013.

Paints, varnishes and similar coatings, printing inks and mastics amounted to 7.6%; “other organic basic chemicals” was just behind, at 7.1%; and perfumes and toilet preparations accounted for 7%, according to the ONS Annual Business Survey.

The CIA suggests that the ONS Index of Production (IoP) gives “more timely” information on changes in industrial production than the Annual Business Survey, however according to the IoP, non-pharma chemical production expanded by almost 4% in 2014, compared with the year before and that strong growth in the latter half of the year and the first two months of 2015 helped the industry to achieve its highest level of output since August 2008 – just about the start of the recession.

On the other side of the coin, pharma production fell, although at a slower rate at the beginning of this year than had been apparent at the start of 2014. A number of reasons for the slowdown in the pharma industry have been put forward.

Chemicals and pharmaceuticals are strong foreign currency earners; they exported goods worth a total of £52.4bn in 2014.

For many years it was argued that the UK’s National Health Service was a magnet for global pharmaceutical companies; its patient records and data, going back to the late 1940s, was claimed to be an invaluable resource for companies seeking to develop new medical products.

The strong pharmaceutical research and development infrastructure in universities across the country, including Imperial and King’s in London; Nottingham; Cambridge, and Manchester, was also claimed to be an attraction.

A number of drugs and therapies have been developed over the years, from penicillin – albeit that it was American companies who commercialised production – through the Tamoxifen breast cancer drug, Inderal beta-blocker and some interesting “accidental” discoveries, such as Viagra.

However, US company Pfizer, which owns the plant at Sandwich, Kent, where Viagra was discovered, announced in 2011 that the facility was to close. At the time of writing, the site is still open but with a much-reduced headcount. It also has a research facility in Cambridge.

According to Steve Elliott chief executive officer at the CIA, the future for the British chemical industry offers challenges and opportunities. Lower oil prices have put downward pressure on energy and feedstock costs; however, producers in the US are able to produce basic petrochemicals at much lower cost.

The weak European economy has reduced demand from the industry’s largest trading partner and reduced the value of the euro, which makes UK exports more expensive – but the European economies are recovering, subject to fallout from events in Greece.

US shale gas imports will be starting late 2015/early 2016 and this should lead to increasing demand and lower production costs. However, as attractive as American shale gas may be, reliance on foreign supplies carries a degree of risk – and that strengthens the case for the exploitation of domestic onshore and offshore unconventional oil and gas reserves, the Association believes.